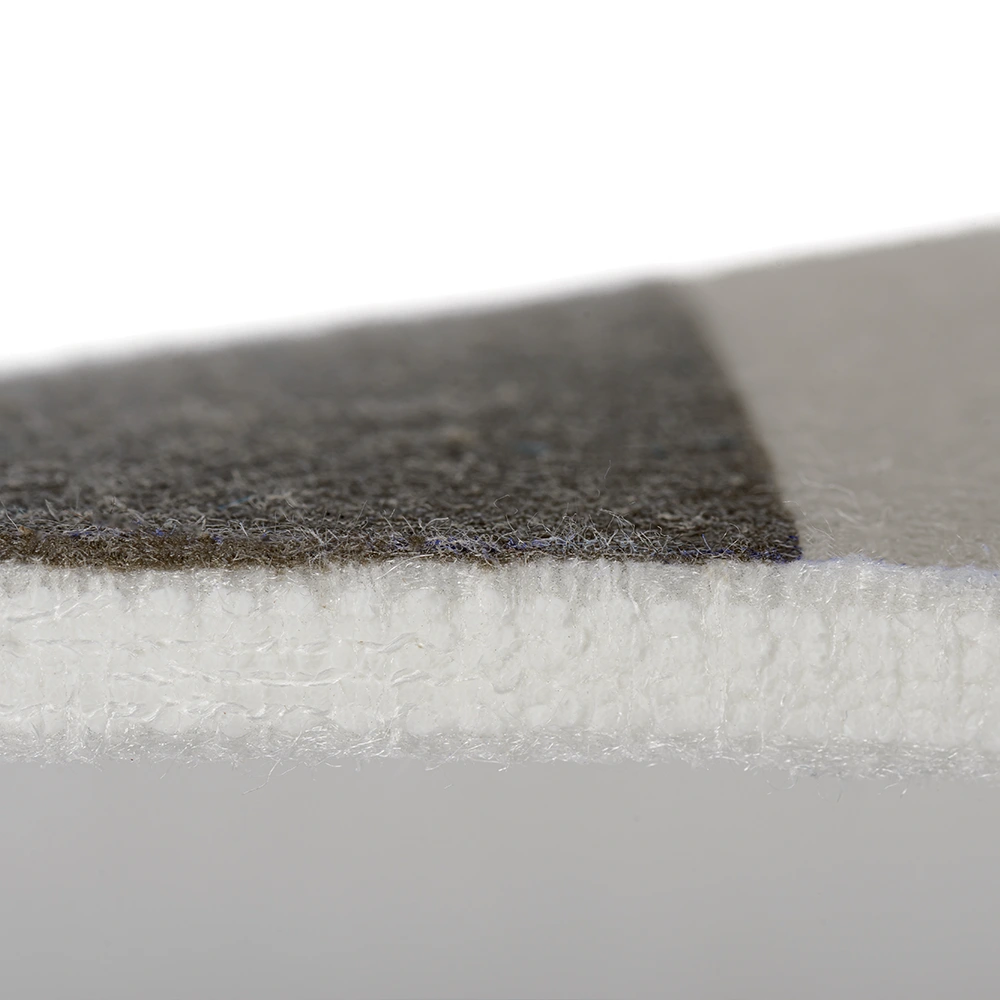

Bricq-Master and Bricq Four are our next generation of top and bottom needled belt, not to be mistaken for old needled-felts, which are no longer used in the corrugated board industry. Its unique structure, composed of a multilayer low density fabric needled with batt-like polyester fibers, gives the fabric both resistance and lightness, as well as exceptional smooth and flatter surface finish. The lighter weight structure also provides energy savings.

The specific structure of Bricq-Master and Bricq-Four also gives the belt a very good permeability and porosity, for optimal evaporation, which means a better flatness and quality of the board, even at higher speeds.

The needling technology also allows a totally integrated seam where the lacing hooks are completely covered on paper side by a flap made of the outer layer of the belt. This feature is particularly suitable for cardboard with a fragile surface finish like board grades with white top kraft liner, E or F flutes or intended for high graphics printing because of the smoother and flatter surface of the needled finish of the belt.

With its four layer woven structure, Bricq-Four has been specially designed for our customers in Asia and Latin America. Bricq-Four is our heavy duty needled belt for corrugators running in rough conditions, thanks to its increased resistance versus Bricq-Master.

Bricq special proprietary G3 coating edge treatment provides higher abrasion and temperature resistance at the edges of the belt while maintaining excellent moisture management properties.

Our unique heat-setting operation provides dimensional stability and reduces noises thanks to a flattened surface finish.

We have more than

800 corrugator belts

in operation in the world !

We have more than 800 corrugator belts in operation in the world !