Heat setting is a term used in the textile industry to describe a thermal process consisting in exposing the textile to controlled heat. The effect of the process gives fibers, yarns or fabric dimensional stability and, very often, other desirable attributes like higher volume, wrinkle resistance or temperature resistance.

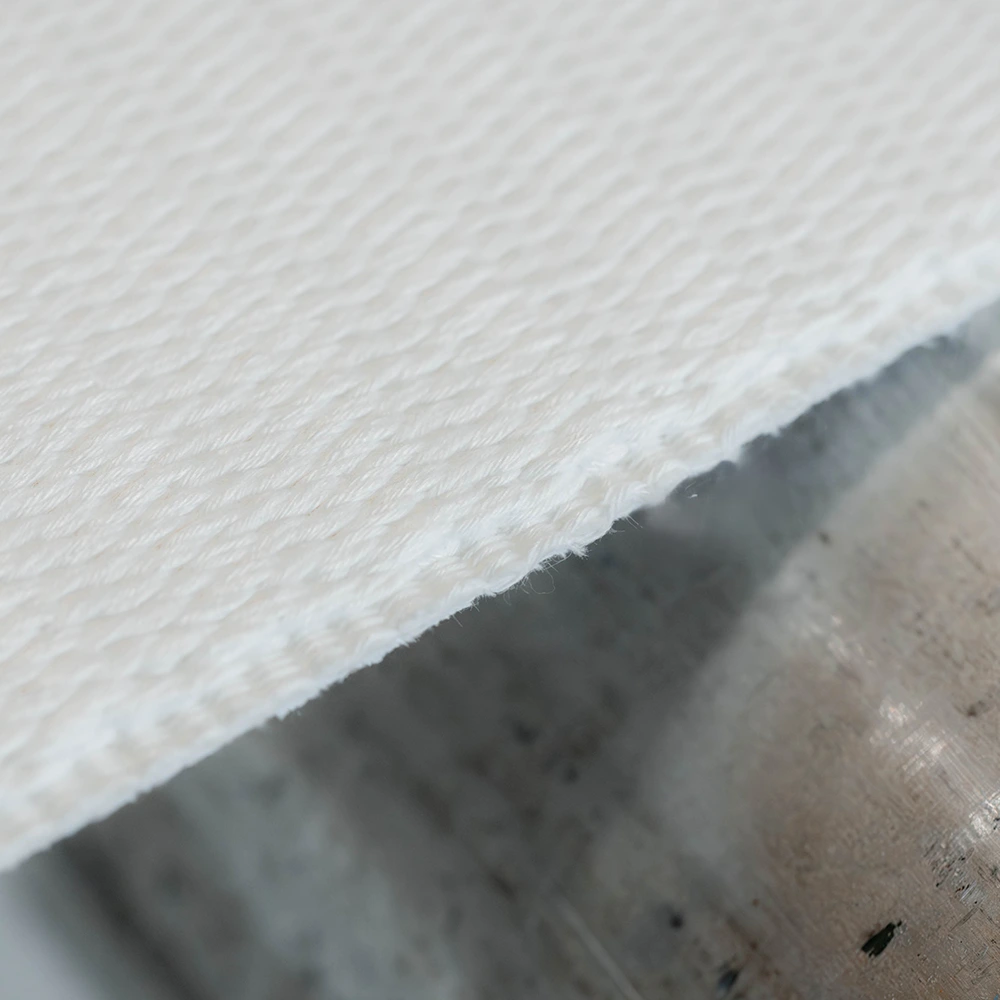

At Bricq, the process of heat setting is made by contact in a dry-heated environment. In this method, the heavy duty fabric is run in contact with heated metal surface cylinders filled with a liquid known as diatherm to uniformly distribute the heat. This is a highly critical operation which will avoid your corrugator belt to stretch and elongate.

In other terms, thanks to our heat setting process our corrugator belts length is stabilized before installation, as opposed to stabilizing during the first months of production. Our belt is thus perfectly adapted to the corrugator belt tensioners. Our belt lengths are calculated to fit the central position of the tensioners so that the belt can be installed easily and with less efforts.

This also explains why we do not need to shorten the length of our belts after the first few months of production by removing a strip, like some other belt manufacturers frequently do.

Heat-setting also provides dimensional stability in cross direction so that our belts do not shrink and nor customers nor corrugator manufacturers have to overspecify the width of the belt.

This process is far more efficient than the one used by manufacturers who purchase and weave heat-set yarns.

All belts manufactured by Bricq are pre-stretched, tensioned and stabilized before their final onward journey to the customer. This benefit offers a belt that is reliable and consistent resulting in enhanced web alignment and a reduction in noise through bounce and movement reduction.

We have more than

800 corrugator belts

in operation in the world !

We have more than 800 corrugator belts in operation in the world !