Corrugator Belts

Your true alternative for high quality corrugator belts

As one of the oldest corrugator belts manufacturer, Bricq stands for quality and innovative products for more than 130 years. Our corrugator belts are used in double facers – also called double backers – in corrugator machines. Their main function is ensure the drying of the corrugated board as well as a smooth transport of the board.

Corrugator Belts

Our belts are exposed to significant stresses from temperature, humidity, pressure, friction, tensile stress. Hence, Bricq corrugator belts have been specially developed to fit and resist this demanding wet and hot environment. Our corrugator belts are three dimensionally woven and thus consist of heavy duty multiple layer fabrics. The resistance to tear, heat and abrasion of the special fibers we use give our belts excellent durability and transport characteristics. This guarantees reliability and efficiency when operating the most important equipment in your corrugated plant.

Drum Laggings

In order to optimize your production process and make the procurement of your consumables easier, Bricq offers you drum laggings and our popular bridge brake lining also knows as Picot Lagging, on top of corrugator belts.

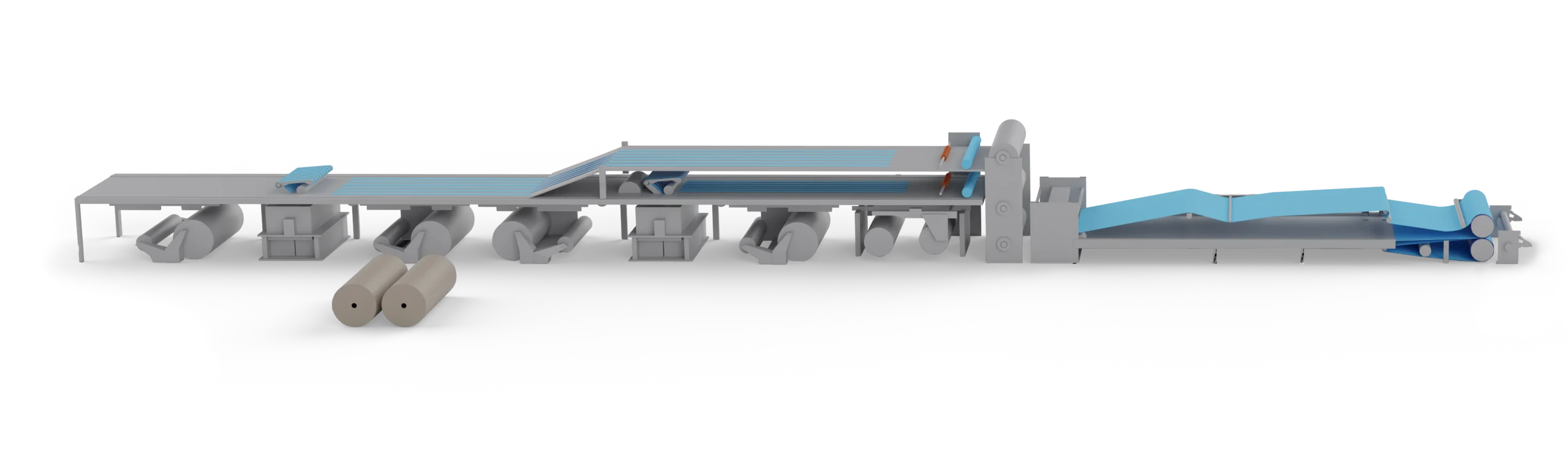

Our textile applications in your corrugator

Bridge Brake Lining

(Bricq-Picot)

Bottom belts

(Bricq-power, master,

track w, track d)

Drum Laggings

(Bricq-Lag55, easylag)

Top belts

(Bricq-power, master,

four, speed)

We can offer the most suitable belt for any machine and product configuration

Our corrugator belts are universal and will fit all corrugator types and models worldwide. Our installed base of more than 800 corrugator belts worldwide in more than 90 countries equip all the corrugator manufacturer brands. Our belts are fitted for high-performance corrugators as well as smaller runs or high-quality specialty board grades corrugators.

Our corrugator belts are specially developed for machines with pressure rolls, surface pressure plates, air hoods or a mix of rolls and plates powered by a chain. Moreover, our research and development team has developed special products in addition to our standard product range in order to fulfil specific customer or technology requirements.

Worldwide Technical Field Service

Because our corrugator belts are critical in your process, our dedicated Technical Service Team, based in Europe, will support you, installing your corrugator belt, checking its wear and behaviour over time and sometimes giving it a treat to extend its lifespan. We also rely on our global network of trained field service technicians covering our main geographies in Asia, Latin America, North America and Africa from our various technical service hubs in Kuala Lumpur, Guangzhou, Buenos Aires, Curitiba, Dallas, Johannesburg, Montréal, and many other locations.

Outstanding supply chain

Our unique production process allow us to cut our corrugator belts to width and edge-treat them right before our finishing operations. We can therefore use delayed differentiation to reduce leadtime on standard universal specifications and even deliver a belt in an outstandingly fast turnaround time in case of emergency. We know your corrugator is the most important asset of your factory and we will never let you down.

BRICQ lacing

You will recognize our proprietary Bricq lacing by the outstanding blue color of its flocking, specially designed to eliminate marking during production.Thanks to our flocking technology and years of experience and craftmanship of our operators and technicians, the splicing of the belt is perfectly flat and even, and there is no contact between the hooks and the corrugated board, nor the heating plates or the pressure system. Our belt will leave no marks on the corrugated board and your corrugator is well protected.

Besides, Bricq lacing is durable, easily repairable breathable and have excellent rolling properties, even at very high speed, above 400 lm/min.

Heat Setting

At Bricq, each of our corrugator belt goes through our heat setting process which consists in fixing the dimension of the belt by running the heavy duty fabric in contact with heated metal surface cylinders. This is a highly technical operation which will significantly reduce your corrugator belt stretching, elongation, and also, shrinkage in the cross direction. All our belts are thus pre-stretched, tensioned and stabilized before their final onward journey to your factory. This benefit offers a belt that is reliable and consistent resulting in enhanced web alignment and a reduction in noise through bounce and movement reduction.

G3 edge treatment

At Bricq, we have developed a unique proprietary edge treatment called G3 coating, a high-technology compound. Its specific formula improves the resistance to high temperatures and abrasion and prevent glue residues to stick to the belt, with no impact on the permeability of the belt. This surface-impregnation treatment is made in our finishing department after the belt is cut to width which gives us flexibility in production through delayed differentiation.

We have more than

800 corrugator belts

in operation in the world !

We have more than 800 corrugator belts in operation in the world !