As corrugators are run in different paper width combinations to find a compromise between the utilization of the corrugator maximum width and the trim waste, the working width of a corrugator can be significantly lower than its maximum width.

Therefore, the edges of a corrugator belt wear faster than the central part of the belt. This is caused by an exposure to higher temperatures and greater abrasion due to the more direct contact between the belt and the hot plates at the double-backer and the exposure to glue residues which could require regular scrapping and cleaning.

To extend the lifespan of the belt, corrugator belts manufacturers have developed different strategies to strengthen the edges of their belts.

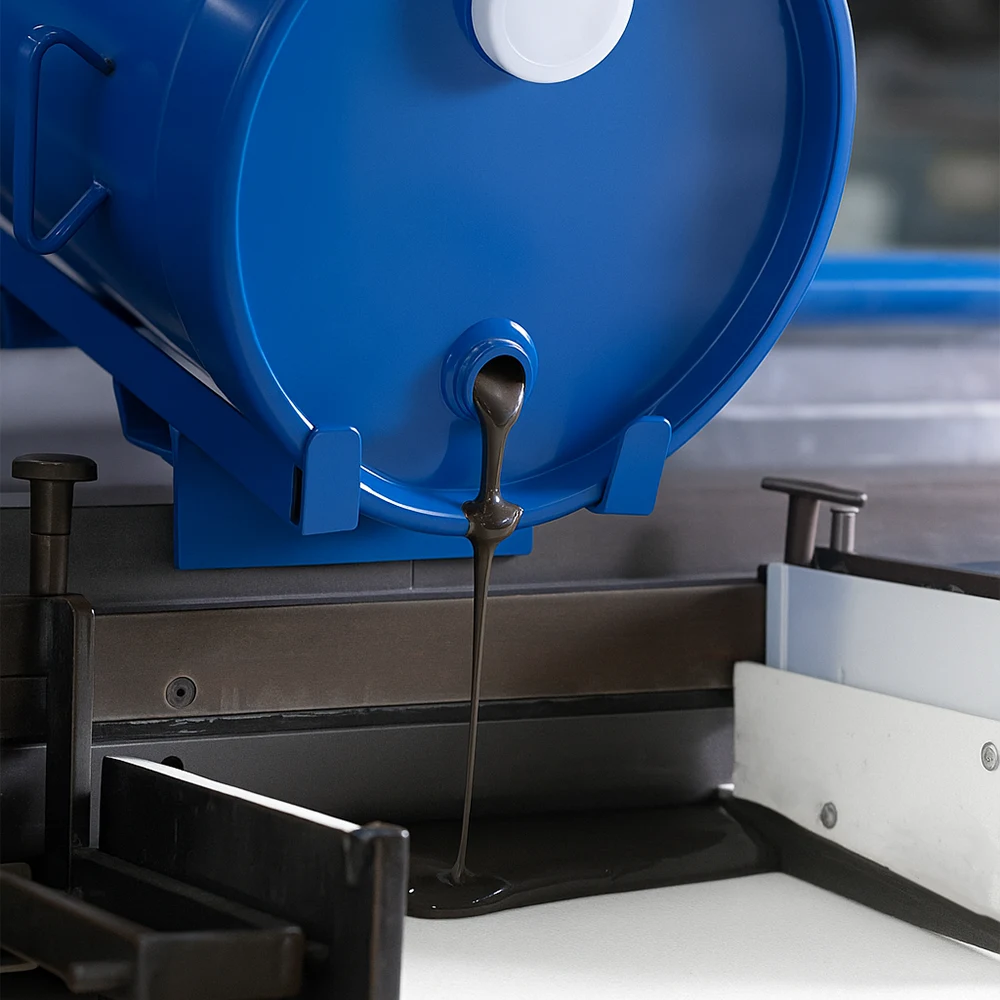

At Bricq, we have developed a unique proprietary edge treament with G3, a high-technology compound, which impregnates the textile fibers on the surface. Its specific formula improves the resistance to high temperatures and abrasion and prevent glue residues to stick to the belt.

With Bricq G3 edge treatment, you can reduce the edge wear of your corrugator belt and increase its lifespan by up to 10% vs aramid-based edges. This is due to Kevlar lower resistance to abrasion at current corrugator hot plates working temperatures nowadays (<180 degrees Celsius).

Another advantage of our G3 versus a Kevlar-woven solution on the edge is that we can easily tailor-made the width of our edge treatment according to your needs.

We have more than

800 corrugator belts

in operation in the world !

We have more than 800 corrugator belts in operation in the world !