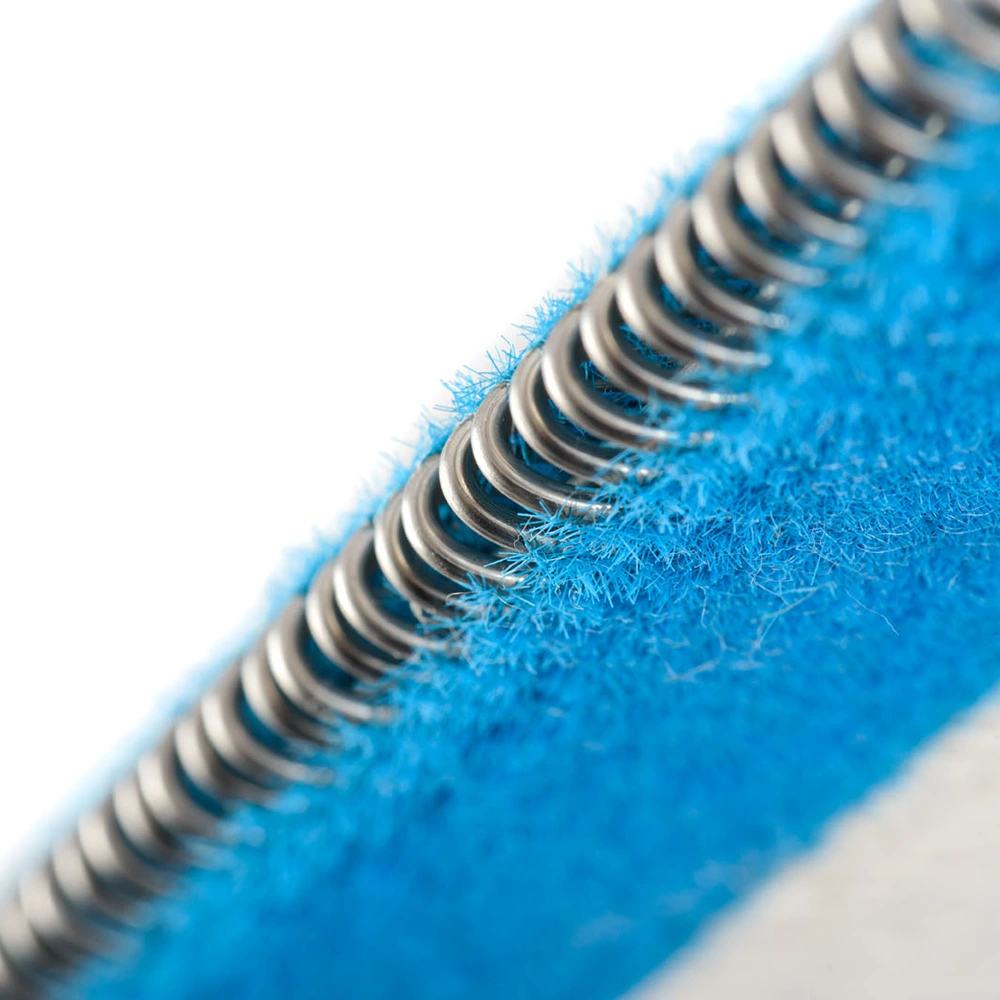

You will recognize our proprietary Bricq lacing by the outstanding blue color of its flocking, specially designed to eliminate marking during production.

The belt is bias-spliced, which means that each connecting end of the belt is cut at a matching slight angle. This allows the lacing to gradually go over the heat plate unit of the double facer instead of the whole splice entering the unit at once. The bias splice optimizes the tracking and guiding of the belt, and reduces its noise.

Our lacing is totally secured by steel hooks and a transversal steel insert for maximum resistance. Due to the fact that our belts are heat-set and do not shrink in the cross direction, we can use a special type of fastener which feature performance-proven hooks welded to a common bar for easier installation with less downtime. The welded common bar holds individual hook legs parallel during the installation process and creates a flat finished splice (no ‘belt wave’). This combination eases the meshing of spliced belt ends and simplifies pin insertion. Our lacing is also pressed and heated into hot jaws to flatten and give the lacing its final structural shape.

Thanks to our flocking technology and years of experience and craftmanship of our operators and technicians, the splicing of the belt is perfectly flat and even, and there is no contact between the hooks and the corrugated board, nor the heating plates or the pressure system parts. Our belt will leave no marks on the corrugated board and your corrugator is well protected.

Besides, Bricq lacing is durable, easily repairable breathable and have excellent rolling properties, even at very high speed, above 400 lm/min. Our Field Service Technicians will certainly be mostly pleased to check your hooks and pin in order to preventively change them.

We have more than

800 corrugator belts

in operation in the world !

We have more than 800 corrugator belts in operation in the world !